Reducing packaging costs can be a smart strategy for your business. Readers, today we will discuss how to reduce packaging costs and custom boxes used for packaging your products, display boxes, best box companies and their packaging processes. So let’s read the entire article very carefully-

What is packaging cost

Packaging cost refers to the cost incurred in designing, manufacturing and distributing packaging materials used to contain and protect products for sale and transport. Packaging is essential for many reasons including product preservation, brand representation, consumer convenience and logistical efficiency. However, packaging costs can vary significantly depending on the type of product, complexity of packaging design, quantity of product packaged, and other factors. For some industries, such as food or pharmaceuticals, packaging cost is an important consideration due to the importance of product safety and shelf life. In addition, there is a growing emphasis on sustainable and environmentally friendly packaging, which can affect packaging costs.

Packaging cost per unit

Packaging costs per unit may vary based on product type, packaging materials used, production volume and other factors. Our product box prices vary from $0.20-$0.50 per unit with free shipping and product display box prices vary from $1-$2.50 per unit. However, I can provide you with a general overview of the components that contribute to packaging costs:

The packaging cost per unit may vary according to the cost of materials used for packaging, such as cardboard boxes, plastic containers, labels, shrink wrap, foam inserts, and any other materials required to protect and present the product. If the packaging includes printing, labeling or custom branding, these costs need to be considered This includes the cost of graphics or label design and production. Moreover labor cost for assembly of packaging, labeling and any other manual work involved in preparing product for distribution

There are costs associated with machinery and equipment used in the packaging process, such as sealing machines, labeling machines and automated packaging systems. If packaging materials or finished products need to be transported to a manufacturing facility or distribution center, transportation costs should be considered. Storage costs for packaging materials and finished products, including warehouse space, shelving and handling. The more units you make, the more fixed costs (such as equipment and setup) can be spread out, potentially reducing the cost per unit.

To calculate the exact packaging cost per unit for a particular product, you need to consider all these factors and then divide the total packaging cost by the number of units packaged. Note that economies of scale (cost per unit decreases as production volume increases) can play an important role in packaging costs. It is also essential to regularly review and adjust these costs as market conditions change and your production volume fluctuates.

Cost of packaging material

The cost of packaging materials can vary widely based on a number of factors, including the type of material, quantity required, quality and where you are sourcing the materials. Additionally, packaging materials can range from basic cardboard boxes to custom-printed packaging, bubble wrap, foam inserts, plastic bags, and more.

Identify the specific packaging materials required for your products. This can include boxes, tape, bubble wrap, foam, labels and any other materials relevant to your packaging. Calculate the number of packaging units you need based on your product volume, shipping frequency and any potential storage requirements. Find suppliers of packaging materials. You can find them locally or online. Compare prices from multiple suppliers to get the best deal.

Reach out to suppliers with your specific requirements and get quotes for the packaging materials you need. Be sure to ask about bulk discounts if applicable. Be sure to account for additional costs such as shipping, custom printing, and storage if you need to order large quantities of materials.

It’s important to remember that packaging costs can be a significant portion of a business’s costs, especially for e-commerce or retail operations. Consider the balance between quality, branding and cost-effectiveness to find the right packaging solution for your products.

Cost-effective packaging ideas

Cost-effective packaging is essential for businesses that want to save money while delivering professional and attractive products to their customers. Here are some cost-effective packaging ideas:

- Minimalist Design: Simplify the design to reduce the need for complex printing, multiple colors or complex details. A clean and simple design not only saves on printing costs but also gives off a modern and stylish look.

- Standard sizes: Choose standard packaging sizes that are readily available and require less customization. This reduces the need for custom tooling and can help you take advantage of bulk purchasing.

- Eco-friendly materials: Consider using recyclable or biodegradable materials for your packaging. Not only is it environmentally responsible, it can also appeal to eco-conscious consumers.

- Multi-use packaging: Design packaging that can be reused by customers. For example, a hard box that can be reused for storage, or packaging that can be converted into a display stand.

- Simple printing techniques: If branding is essential, consider using cost-effective printing techniques such as one-color printing, embossing or debossing.

- DIY Packaging: Depending on the nature of your product, you can explore the option of letting customers assemble parts of the packaging. This can save labor costs and create a sense of interaction with your product.

- Reusable packaging: Consider using packaging that customers can reuse, such as a tote bag or a durable box. This not only reduces waste but also increases the perceived value of your product.

- Digital Printing: For short runs or personalized packaging, digital printing can be more cost-effective than traditional offset printing because it does not require expensive setup fees.

- Lightweight Materials: Choose lightweight materials that still provide adequate protection for your product. It can also reduce shipping costs.

How to reduce packaging cost

Here are some strategies to help you reduce packaging costs:

- Right-sized packaging: Choose packaging that fits your product without taking up too much space. Oversized packaging not only wastes materials, it also increases shipping costs.

- Material Selection: Use cost-effective materials that provide adequate protection. Consider using recycled or eco-friendly materials if appropriate for your brand and product.

- Bulk Purchases: Buy packaging materials in large quantities to take advantage of volume discounts from suppliers.

- Standardize packaging: If you have multiple products, try to standardize packaging size and materials. This can save production and storage costs.

- Optimize Design: Redesign packaging to reduce the amount of material used while maintaining product safety and attractiveness. This can reduce the use of different sizes or redundant features.

- Automation: Invest in packaging machinery and automation wherever possible. Automation can improve efficiency and reduce labor costs.

- Supplier Negotiations: Regularly review and negotiate prices with packaging suppliers. Consider asking for bids from multiple suppliers to get the best deal.

- Economical Shipping: Optimize the shipping process to reduce costs. Negotiate shipping rates with carriers, consider alternative shipping methods, and explore shipping software to find the most cost-effective options.

- Continuous Improvement: Regularly review your packaging processes and costs to identify opportunities for further optimization.

Remember that while cost reduction is essential, it is important to balance product quality, safety and meeting customer expectations. Make sure you implement any changes that align with your brand and your target market’s needs.

Which is the best Custom Box and Counter Display Box manufacturing company?

Dear Customer, The Best Custom Box and Counter Display Box Manufacturing Company is “The Display Packaging”. If you are looking for custom boxes or packaging for your business, this might be the best solution for you. Hopefully this company will be able to meet your budget-friendly design needs.

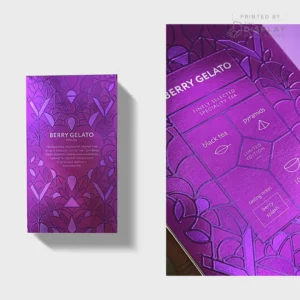

The company manufactures custom packaging boxes for a variety of industries and box styles such as product boxes, display boxes, eco-friendly shipping boxes, corrugated cartons, cosmetic packaging boxes, mailer boxes and more, which can be found on their website- https://thedisplaypackaging .com/

That’s not all, the company’s user-friendly website has live chat, so you can talk to a helpful customer support representative without any waiting time. After a quick chat or form submission, a company representative will contact you with a price estimate and collect your artwork to begin the production process.

To confirm the order click on the link below and fill the form: https://thedisplaypackaging.com/contact/

To make any suggestions or complaints or to talk to us please contact:

Phn: +8801612969696

Email: info@thedisplaypackaging.com

Stock box company products

I can provide you with a general overview of the types of products a stock box company can offer based on common packaging materials and solutions available in the industry. Which is described below-

- Folding cartons: These are often used for retail packaging, such as cosmetics, pharmaceuticals and consumer goods. They are usually made from paperboard and can be customized with printing and special finishes.

- Rigid Box: These high-end boxes are used for luxury products like electronics, perfume or jewelry. They are sturdy and visually appealing, often customized with high-quality printing and embossing.

- Corrugated Displays: Point-of-sale (POS) displays made from corrugated cardboard are used to display products in retail settings. These can be floor displays, counter displays or end-cap displays.

- Protective Packaging: Companies can provide various protective solutions such as bubble wrap, foam inserts and void fill materials to ensure that products are well protected during shipping.

- Specialty boxes: Some companies offer unique packaging solutions tailored to specific industries, such as food packaging, medical packaging, or e-commerce packaging.

- Corrugated boxes: They are versatile, durable and commonly used for shipping and storing various products. They come in a variety of sizes, including standard RSC (Regular Slotted Container) boxes, custom boxes and special packaging for specific industries.

Packaging cost in logistics

Packaging costs are an essential component of logistics, especially in supply chain management. Packaging serves multiple purposes including product protection, transportation convenience, enhancing brand image and ensuring product integrity. Logistics professionals aim to balance these factors to reduce packaging costs by ensuring products arrive at their destination safely and in good condition. Effective packaging design can have a significant impact on overall supply chain efficiency and customer satisfaction.

Packaging cost for food products

Packaging costs for food products can vary widely based on a number of factors, including the type of packaging material, package size and shape, production volume, and specific requirements of the food product. Here are some key considerations that affect packaging costs:

- The type of material used for packaging significantly affects the cost. Each material has its own cost structure and factors such as availability, durability and environmental considerations can also affect the price.

- More complex and custom packaging designs may require special equipment, molds or printing processes, resulting in higher costs.

- The size and shape of the package affects the amount of material required and the complexity of the manufacturing process. Irregular sizes can increase costs.

- High-volume production often lowers per-unit packaging costs due to economies of scale. Smaller production runs can result in higher costs per unit.

- If the packaging requires complex printing, branding or labeling, this can increase costs. High quality printing and special finishing can be more expensive.

- Packaging designed to be environmentally friendly can have a higher upfront cost than conventional packaging options.

- If packaging affects the efficiency of transportation or storage, it can affect overall logistics costs.

- In a competitive market, companies can invest in attractive and innovative packaging, which can affect overall packaging costs.

Conclusion

Remember, the best strategies for reducing packaging costs will depend on your specific product, industry and business model. Regular evaluation and refinement of your packaging practices can reduce costs while aligning them with your business goals. Readers, I hope you have understood how to minimize packaging costs for a company to maximize profits. So if you like today’s article then definitely share with your friends and stay with our website to get new information.